It‘s a “Sprint” to the finish

Extremely smooth surfaces

in just seconds

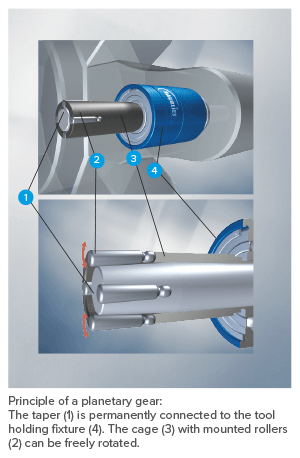

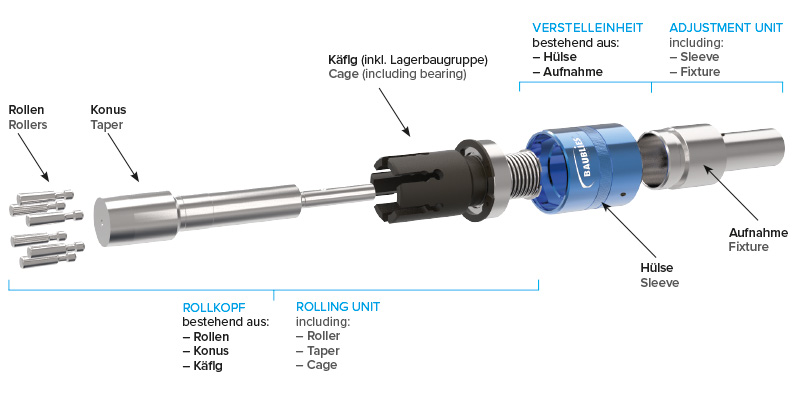

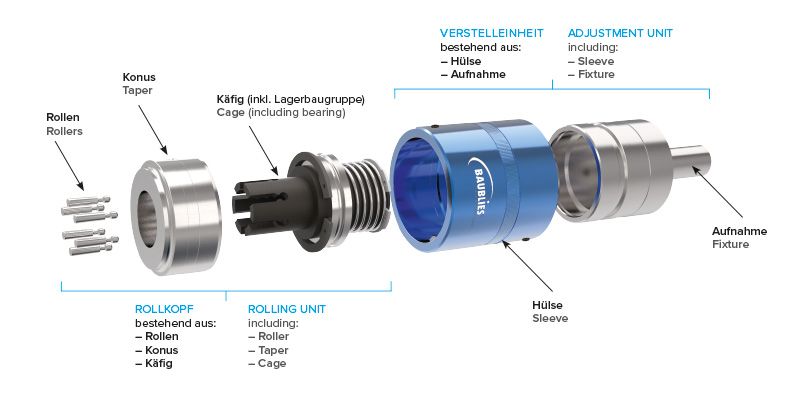

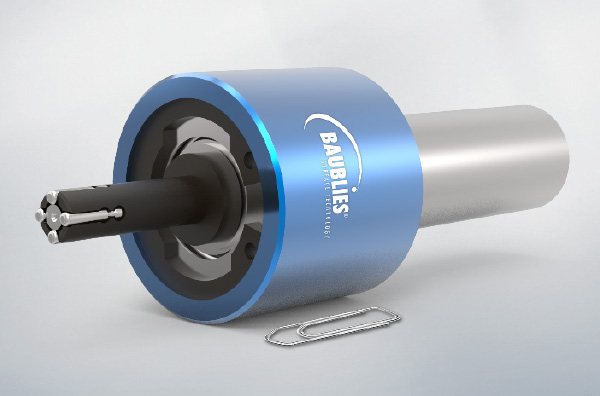

Depending on the burnishing task various numbers of hardened rollers are arranged in a cage. The machining times are kept short by using several rollers simultaneously. During roller burnishing with multi-roller tools, a roll-off process with kinematics similar to those of a planetary gear results. A taper supports the rollers and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller. Therefore multi-roller burnishing tools are particularly suitable for small and filigree workpieces.

Baublies multi-roller burnishing tools are available as standard tools for an extremely broad range of interior and exterior applications. We also develop individual solutions for your special application.

Advantages

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

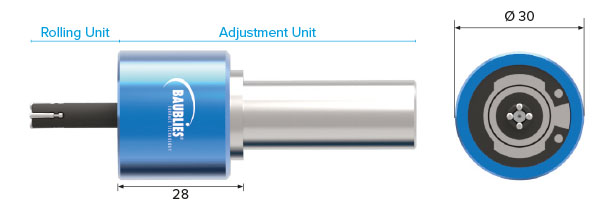

MULTI-ROLLER BURNISHING TOOL

for internal machining

Assembly of an internal roller-burnishing tool:

A taper supports the rollers in a cage and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting of the taper relative to the roller.

TIP:

When setting up a tool, the revolution speed can be considerably reduced, however the feed rate per revolution is not to be decreased. When conducting roller burnishing under unfavorable conditions, e.g. when using high-strength materials with insufficient lubrication or very deep holes, it is advisable to reduce the revolution speed.

Advantages

- Simple to use

- Compact design available for machines with limited tool space

- Can be adapted to all materials by means of four spring elements (included in delivery)

- Diamond radii from 0.4–5 mm available

- Diamond indexed for multiple machining

- Highest surface quality and hardening

- Universally applicable

- Ideal for contour machining

- For hard machining and thin-walled workpieces

- Tolerance compensation through spring-loaded design

- Changeable diamond insert

- Re-grinding of the diamond is possible

- Cost-effective/low investment

MULTI-ROLLER BURNISHING TOOL

for external machining

Assembly of an external roller-burnishing tool:

A taper supports the rollers in a cage and provides the contact force for forming the material. The rolling diameter is adjusted by axial shifting

of the taper relative to the roller.

TIP:

When setting up a tool, the revolution speed can be considerably reduced, however the feed rate per revolution is not to be decreased. When conducting roller burnishing under unfavorable conditions, e.g. when using high-strength materials with insufficient lubrication or very deep holes, it is advisable to reduce the revolution speed.

Advantages

- Workpiece is not subjected to lateral forces

- Reduced machining times

- Harder surface layers

- Increase in fatigue strength

- Greater contact area due to plateau formation

- Higher surface resistance to wear and corrosion

- Increase in material fatigue limits

- Reduced sliding friction coefficients, constant dimensions and high fitting accuracy

- Environmental sustainability (as no grinding dust is produced)

- Suitable for use on all standard machine tools

Internal roller burnishing tool PICCOLINO

for blind hole and through hole

PICCOLINO internal roller burnishing tools are a particularly compact design for use on machines with limited working space, such as multi-spindle and Swiss-Type lathes or rotary transfer machines.

Advantages

- Very short machining time

- Surface finishes of the highest quality

- High productivity

- Fast return of invest

- Easy to maintain

- Slim design

- Usable on all common machines

WERKZEUG 4

Lorem ipsum dolor sit

Vorteile

- Einfache Handhabung

- Kompakte Ausführung für Maschinen mit eingeschränktem Werkzeugraum verfügbar

- Mittels vier Federelementen an alle Werkstoffe adaptierbar (im Lieferumfang enthalten)

- Glättdiamantradien von 0,4 – 5 mm verfügbar

- Glättdiamant indexiert für Mehrfachbearbeitung

- Höchste Oberflächengüte und Verfestigung

- Ideal für Konturbearbeitung

- Für Hartbearbeitung und dünnwandige Werkstücke

- Toleranzausgleich durch Federung

- Austauschbarer Diamantträger

- Der Glättdiamant kann nachgeschliffen werden